4 Easy Facts About Premier Aluminum Llc Described

Table of ContentsAbout Premier Aluminum LlcUnknown Facts About Premier Aluminum LlcThe Facts About Premier Aluminum Llc UncoveredSome Of Premier Aluminum Llc

(https://issuu.com/premieraluminum)Typically, a buyer's primary obligation was to find qualified and receptive distributors. In some instances, purchasers assumed that any distributor going to contractually fulfill the purchase demand was qualified. Using reduced cost and unqualified vendors can cause high quality issues, and threw away time and cash in the long run. To assist you via the process, here are some things to consider when picking the right steel casting vendor.

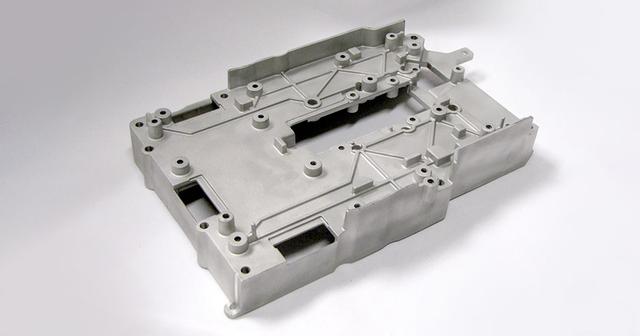

A firm that just makes use of the investment spreading procedure will certainly attempt to market you on why that procedure is best for your application (Casting Foundry). What if utilizing the sand spreading process is best for you and your needs? Rather, seek a vendor that uses a series of casting processes so the most effective option for YOU is selected

If functioning with a single resource for all of your spreading requires is essential to you, the supplier requires to be diverse in its abilities. When combined with other integrated abilities, this can aid streamline and compress the supply base. When selecting the right spreading distributor, careful consideration ought to be provided to quality, service, and cost.

Some Known Factual Statements About Premier Aluminum Llc

Buyers progressively choose casting providers who have machining capabilities. If the spreading distributor uncovers a concern throughout machining, the trouble is solved quicker with no conflict over whose mistake it is.

Trouble or no, integrated machining streamlines the supply chain and minimizes taking care of time and delivery cost prior to the product makes it to the consumer. What do you require from your casting distributor? Are you trying to find somebody to simply supply a metal part to your doorstep or do you require a lot more? As an example, if you do not have in-house metallurgy knowledge, confirm that the vendor can offer advice in choosing the proper alloy based upon your particular application - Foundries in Wisconsin.

Some factories are minimal or specialized. Make sure the provider can satisfy all your product or alloy requirements to get rid of the requirement for multiple providers.

Not known Details About Premier Aluminum Llc

Research the vendor's web site. Talk to a sales rep or service partner.

Light weight aluminum is likewise lightweight and has great rust resistance, making it ideal for applications where weight and sturdiness are very important aspects. Furthermore, light weight aluminum casting is an affordable technique of manufacturing, as it needs less energy and resources than other approaches. Iron spreading, on the other hand, includes pouring molten iron into a mold and mildew to develop a preferred shape.

The Only Guide to Premier Aluminum Llc

Iron spreading is also able to hold up against heats, making it ideal for use in applications such as engine components and commercial machinery. Iron casting can be a lot more pricey than aluminum casting due to the greater cost of raw products and the power needed to thaw the iron. When making a decision in between light weight aluminum casting and iron casting, it is necessary to consider the certain demands of the application.

In conclusion, both light weight aluminum casting and iron spreading have their own unique benefits and drawbacks. There are three sub-processes that fall under the group of die spreading: gravity die casting (or irreversible mold and mildew casting), low-pressure die casting and high-pressure die spreading. To get to the finished item, there are three primary alloys made use of as die spreading material to pick from: zinc, light weight aluminum and magnesium.